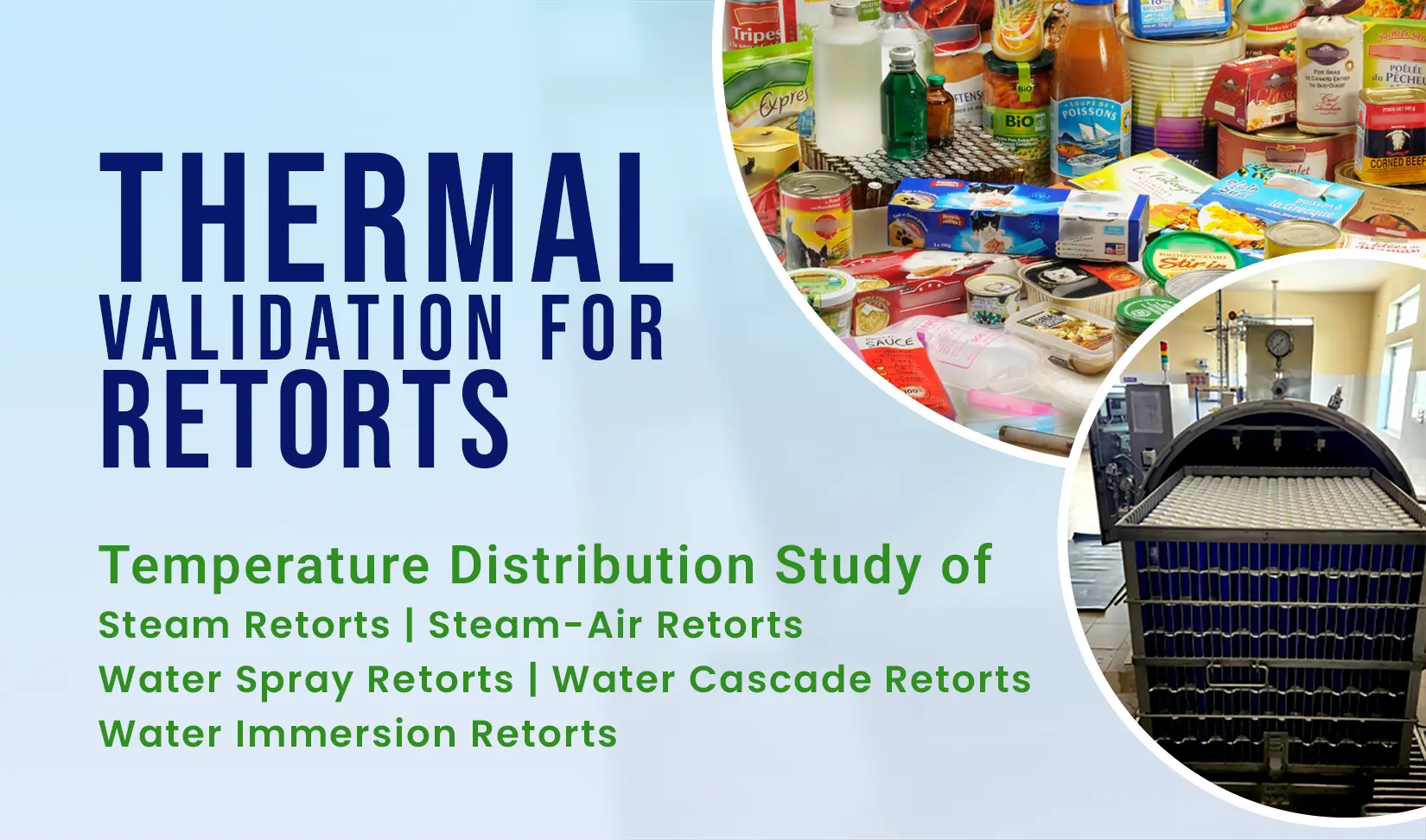

Comprehensive Solutions for Qualification and Validation in Retort Sterilization Retort sterilization is a fundamental process in the food processing industry,...

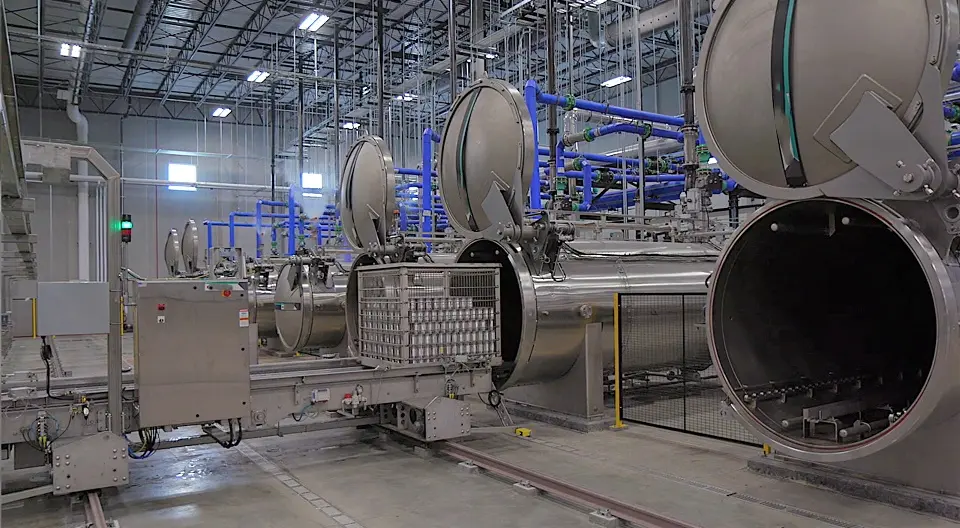

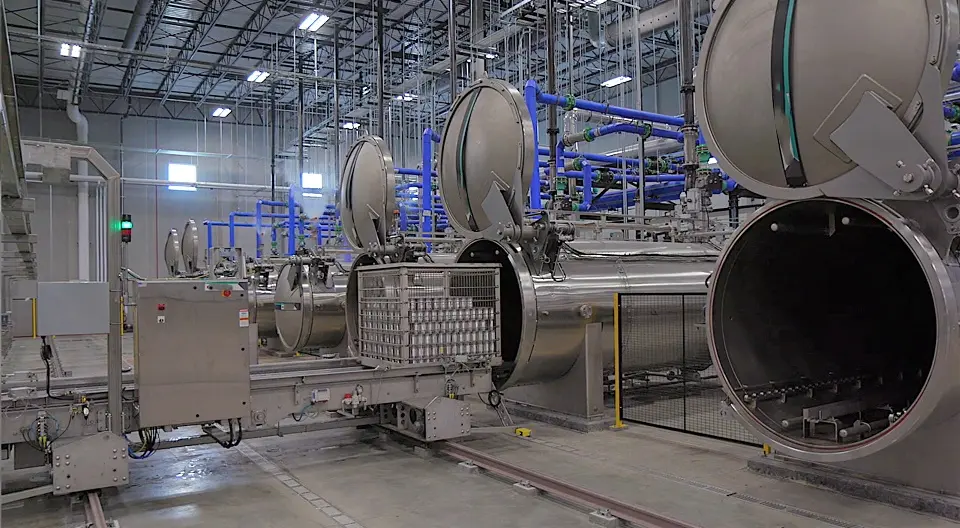

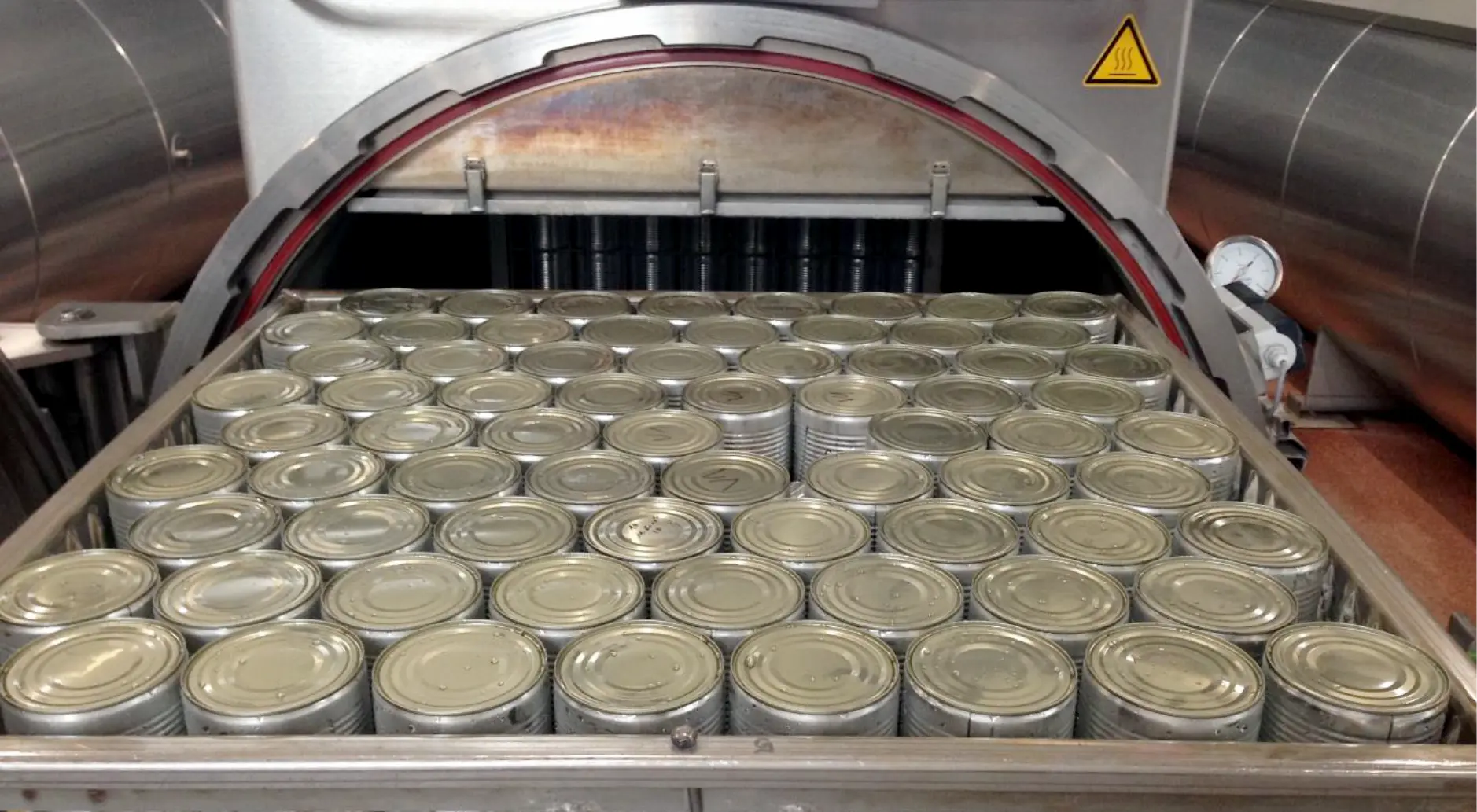

Hydrostatic retorts are essential devices utilized primarily in the food processing and pharmaceutical industries. Their primary purpose is to ensure the sterility and safety of products by employing a process that integrates both high pressure and temperature. This method is crucial for effectively eliminating harmful microorganisms, making it vital for industries that demand stringent safety standards.

The operational principle of hydrostatic retorts revolves around the utilization of pressurized steam to achieve the desired temperature quickly and consistently across all product surfaces. In a typical process, packages are subjected to a controlled environment where steam is introduced, raising the temperature to a predetermined level. Simultaneously, the pressure is adjusted to prevent the bottles or containers from bursting, ensuring that the integrity of the packaging remains intact throughout the process. As a result, this method not only enhances sterilization but also preserves the nutritional and organoleptic qualities of the product.

Modern hydrostatic retorts are equipped with advanced technologies that significantly improve their efficiency and reliability. These include automated controls that allow for precise monitoring of pressure and temperature throughout the process, reducing human error and ensuring consistency in product safety. Furthermore, contemporary designs often incorporate features such as energy recovery systems, which help in minimizing resource consumption and lowering operational costs. Additionally, data loggers and reporting systems are increasingly prevalent, enabling manufacturers to maintain regulatory compliance and streamline their quality assurance processes.

The significance of hydrostatic retorts extends beyond mere sterilization; they are pivotal in enhancing product shelf life, which is essential for both consumer safety and commercial viability. By investing in state-of-the-art hydrostatic retorts, companies can assure their stakeholders of high-quality products, thus fostering trust and reliability in the marketplace.

The validation process for hydrostatic retorts encompasses various challenges that must be carefully addressed to ensure compliance with regulatory standards and to maintain product quality. One prominent issue is the ever-evolving landscape of regulatory compliance, which can pose difficulties for manufacturers. Different regions may have varying requirements, and staying updated on the latest industry standards is crucial. Failing to adhere to these regulations can lead to significant legal ramifications and compromise the integrity of the manufacturing process.

Another major challenge is the consistency in product quality, which hinges on the effectiveness of the validation protocols implemented. Inadequate validation procedures can lead to variances in the processing of food products, resulting in potential safety risks for consumers. Manufacturers must develop robust methodologies that thoroughly assess each step of the hydrostatic retort process to ensure that the desired quality is achieved consistently across batches.

Documentation also plays an essential role in the validation process. Maintaining thorough and accurate records is not only a regulatory requirement but also a critical component of quality assurance. Gaps in documentation can obscure the traceability of the production process and may hinder the ability to respond effectively to any issues that arise post-production. It is imperative that companies invest the necessary resources into developing comprehensive documentation practices that capture all relevant information throughout the hydrostatic retort validation process.

Furthermore, establishing effective validation protocols is inherently complex. Common pitfalls include a lack of collaboration between departments, incomplete data collection, and an overly simplistic approach to validation methodologies. These issues can negatively impact the overall safety and efficacy of the hydrostatic retort processes, ultimately jeopardizing product reliability within commercial applications. Addressing these challenges requires a proactive approach, involving a commitment to continual improvement and the adoption of best practices in validation.

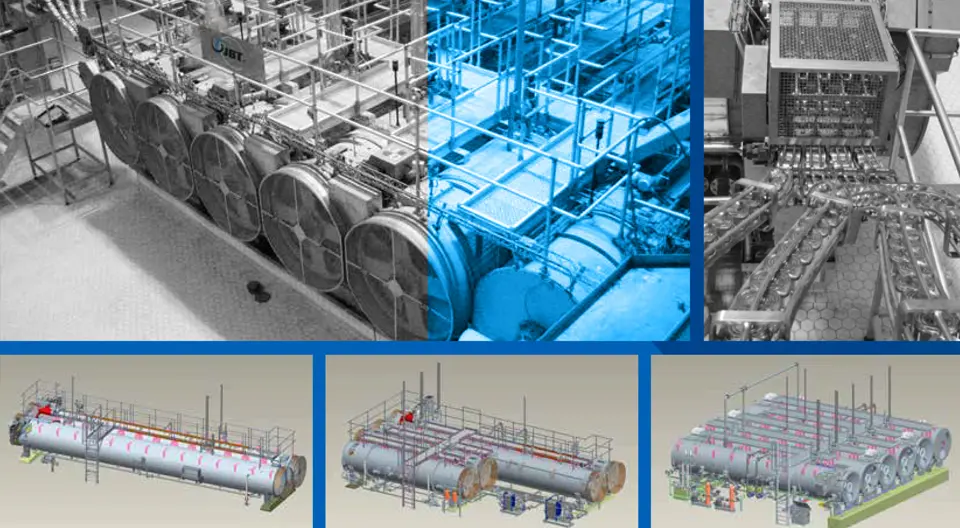

Thorough hydrostatic retort qualification and validation are essential for ensuring food safety and maintaining regulatory compliance. TST recognizes the dynamic needs of clients within this demanding industry and offers a comprehensive suite of solutions tailored to meet those specific requirements. Key among these offerings is expert consulting services, which provide clients with the necessary guidance to navigate the complexities of retort systems. TST’s consultants leverage their extensive knowledge and experience to offer strategic advice on regulatory standards, best practices, and operational efficiency, ensuring that clients are well-prepared for compliance.

Moreover, TST delivers specialized equipment solutions that are crucial for effective hydrostatic retort operations. This includes the supply of high-quality retort systems and essential ancillary equipment designed to meet various production scales. TST works closely with manufacturers to ensure all equipment meets stringent safety and performance criteria, which ultimately aids clients in achieving their operational objectives. The firm’s dedication to quality not only supports compliance but also enhances the overall production process.

In addition to consulting and equipment supply, TST places significant emphasis on training programs for client staff. Understanding that human expertise is a vital element in the operational success of retorts, TST offers tailored training sessions designed to enhance the technical competencies of operators. These training programs cover essential topics such as equipment handling, safety protocols, and regulatory guidelines, equipping participants with the knowledge necessary to maintain high standards of quality and efficiency.

By adopting a holistic approach that combines cutting-edge technology with unparalleled expert knowledge, TST helps clients obtain optimal results in hydrostatic retort qualification and validation. This integrated strategy not only fosters compliance but also drives operational excellence across the industry.

In recent years, TST has established itself as a leader in providing comprehensive solutions for the qualification and validation of hydrostatic retorts, transforming industry practices with measurable success. One notable case study involves a major food processing company that faced challenges with their existing retort systems, which were struggling to meet both efficiency and compliance standards. After collaborating with TST, the company implemented our bespoke qualification process, resulting in a 30% increase in production throughput and a significant reduction in product recalls due to regulatory non-compliance. Client testimonials highlight not only the tangible benefits achieved but also TST’s extensive expertise in navigating complex regulatory landscapes, ultimately inspiring confidence in our capabilities.

Another success story comes from a pharmaceutical manufacturer that sought to enhance the safety and effectiveness of its sterilization processes. By working with TST, they adopted advanced validation techniques tailored to their specific requirements. This partnership ultimately streamlined their operational processes, demonstrated by improved quality assurance metrics and successful regulatory audits. Feedback from the client emphasized TST’s proactive approach, stating that our insights and recommendations led to a better understanding of best practices for hydrostatic retort systems and enhanced team training sessions. The evident shift in operational efficiency underscores the effectiveness of implementing TST’s solutions in achieving regulatory adherence.

Furthermore, a smaller manufacturer specializing in canned goods approached TST to improve their hydrostatic retort qualification after experiencing frequent downtime due to underperforming equipment. Through our detailed validation process and targeted training, the client experienced a turnaround, reducing downtime by 40%, which resulted in substantial cost savings and better product quality. Customer testimonials illustrate the value of TST’s dedicated support, highlighting that our expertise instilled confidence in their manufacturing processes and contributed to long-term improvements. These case studies exemplify TST’s commitment to driving success in hydrostatic retort qualification and validation, reinforcing our position as a trusted partner in this critical area.

Comprehensive Solutions for Qualification and Validation in Retort Sterilization Retort sterilization is a fundamental process in the food processing industry,...

Complete Solutions for Qualification and Validation of Pasteurization Tunnels Pasteurization tunnels are key components in the food and beverage processing...

Complete Solutions for Cooker Cooler Qualification and Validation Cooker cooler qualification and validation often require tailored solutions to ensure complete...

Complete Solutions for Smoke House Qualification and Validation In the realm of food processing and preservation, smoke houses play a...

Complete Solutions for Hydrostatiс Retort Qualification and Validation Hydrostatic retorts are essential devices utilized primarily in the food processing and...

Choosing the Right Retorting System for Your Containers and Products Retorting systems play a pivotal role in the food packaging...

Thermal validation is a crucial aspect of food processing that involves determining the effectiveness of heat treatment methods, particularly in...

In-Container Sterilization – Ensuring Commercial Sterilization Through Critical Factors as per USFDA Guidelines Introduction:The term “Commercial Sterilization” refers to a...

Ultimate Challenge in Retort Process: Finding the Balance between Food Safety & Quality For low-acid foods packed in the hermetically...

At TST, we offer advanced process authority and validation services in support of thermally processed shelf-stable food products. Our teams are industry experts and come well-equipped with industry-leading thermal validation equipment