For low-acid foods packed in the hermetically sealed containers, the temperature during the retort processing is absolutely critical. It directly impacts both food quality and food safety. The food industry constantly juggles this challenge: getting products safe without compromising their appeal and taste. While using high temperatures for extended periods effectively knocks out bacteria and ensures safety, it can unfortunately degrade organoleptic qualities – things like taste, color, texture, and other key product properties.

Fig : Hermetically sealed product filled containers being loaded into the retort machine for thermal processing.

Generally, the industry makes a conscious trade-off, sacrificing a bit of quality to boost safety and extend shelf life. At the same time, retort suppliers are really focused on developing technologies that help optimize food quality without ever cutting corners on safety. A perfectly uniform heat distribution inside the retort chamber is non-negotiable. This prevents any “cold spots” and minimizes the time spent at the “slowest heating point.” Understanding these concepts is vital, and they’re often hot topics in discussions. A cold spot means any area in the retort where the sterilization temperature isn’t met within the recipe’s specified time. It’s also a cold spot if the temperature is reached too late, needing an unacceptable extension of the schedule, which can lead to overcooking or even ruining part or all of the batch.

The slowest heating point still affects the overall quality of the food product, though usually not to the point of needing an excessive extension of the scheduled process time. Both cold spots and other slow heating points are typically found in the spaces between containers. Their exact location can shift depending on the packaging’s size and shape, which is why you absolutely need to get temperature distribution study for every single packaging format.

Retort manufacturers are prioritizing technologies that deliver rapid and uniform heating. Their goal is to completely eliminate cold spots and minimize slow heating zones, ensuring the best possible thermal uniformity across the entire batch. Come-up time (CUT) is the time it takes for the retort to reach the required processing temperature after the heating medium (usually steam) has been introduced. Essentially, it’s the time it takes for the retort to heat up from the start of the heating process until it reaches the target sterilization temperature.

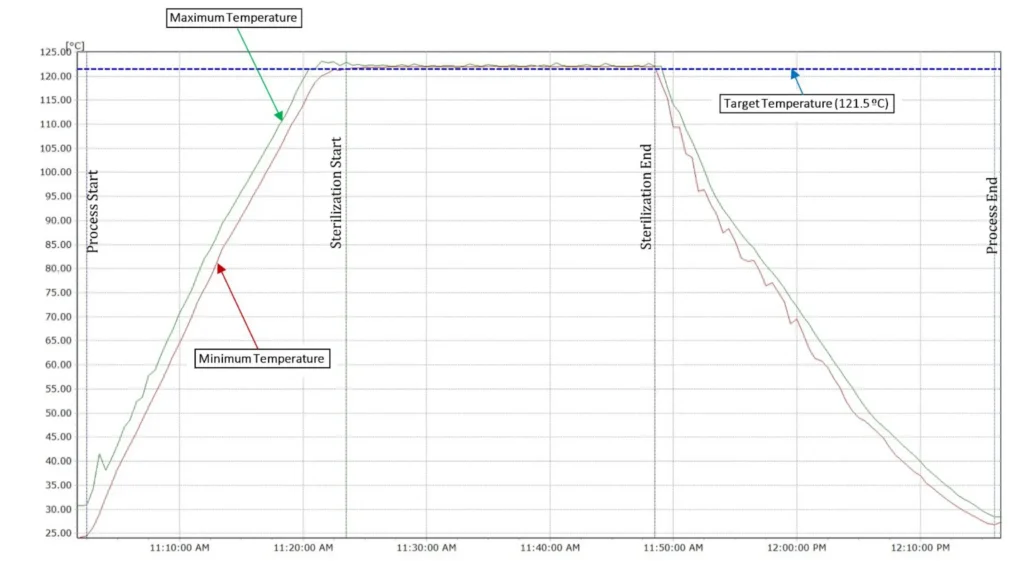

Fig : Min-Max Temperature variation inside Retort plotted against time.

Once all points are at the retort temperature, the next challenge is maintaining them within a really tight range of variation. High-quality retorts manage to keep all points within an impressive +/- 0.5 ºC (+/- 0.9 ºF). If the temperature drops below the validated setpoint / scheduled process temperature for the recipe, that’s considered a deviation and needs to be handled immediately according to your established quality control protocols.

To prevent normal control fluctuations from triggering a process deviation, the retort’s control setpoint should be set 0.5 ºC above the minimum sterilization temperature determined during recipe validation (for example, if the minimum temperature is 121.5 ºC, set the operating temperature at 122.0 ºC).

Heat distribution testing inside the retort and recipe validation are typically carried out by Thermal Process Authorities accredited by the FDA or other recognized food safety organizations. Their specialized expertise is indispensable for striking that optimal balance between safety and quality.

At TST, we offer advanced process authority and validation services in support of thermally processed shelf-stable food products. Our teams are industry experts and come well-equipped with industry-leading thermal validation equipment