Analysis of product formulation, packaging specifications, and desired shelf-life to determine thermal processing requirements.

Thermal process development & validation for low acid canned foods (LACF) as well as acid or acidified food (AF) products packed in any type of containers. We validate all kind of sterilizers and pasteurizers.

We specialize in thermal process development and validation for a wide range of products and container types, helping you achieve optimal product quality while ensuring food safety.

Validation services for low acid, high acid and acidified products in rigid, semi-rigid and flexible containers.

Temperature distribution, heat distribution and heat penetration studies for precise process establishment.

Optimization of thermal processes to improve final product quality and reduce processing time.

Container sterilization is essential for food safety and extending product shelf life. This blog explores the importance of thermal processing methods for low acid and acidified foods, the challenges faced in sterilization, and the role of validation in safeguarding against foodborne pathogens. Learn about innovative solutions offered by Thermosoft Technologies, a leader in the field, addressing the unique sterilization needs of various packaging materials. Discover how advancements in food preservation technologies are shaping the future of the food industry, ensuring quality and safety for consumers.

Analysis of product formulation, packaging specifications, and desired shelf-life to determine thermal processing requirements.

Temperature and heat distribution studies to ensure uniformity of thermal treatment throughout the system.

Precise measurement of heat penetration to the slowest heating point within the product and container.

Scientific determination of optimal thermal process parameters based on collected data and food safety requirements.

In the realm of food safety, the selection of packaging materials is crucial, as it directly impacts how effective sterilization processes are during food preservation. Various types of containers, including metal, glass, and plastic, each offer unique properties that warrant distinct sterilization protocols. Understanding these characteristics is essential for optimizing thermal processing solutions tailored by companies such as Thermosoft Technologies.

Metal containers, commonly used in canned foods, provide an excellent barrier against bacteria and external contamination due to their durability and resistance to environmental stressors. However, the thermal conductivity of metals allows for rapid heat transfer, necessitating precise control of the thermal processing parameters to ensure that the interior of the can reaches and maintains the required temperature for effective sterilization. Thermosoft Technologies utilizes sophisticated thermal processing solutions that consider these factors, allowing for safe and effective sterilization of metal containers.

Glass containers, on the other hand, are widely appreciated for their inert nature, meaning they do not react with food contents. This property reduces the risk of chemical contamination, making glass an ideal choice for many food products. The challenge with glass containers lies in their heat retention and the risk of thermal shock. The sterilization process must therefore be carefully calibrated to avoid potential breakage. Thermosoft Technologies adapts its sterilization techniques to mitigate such risks, ensuring that glass containers are subjected to appropriate temperature gradients throughout the process.

Plastic containers, while versatile and lightweight, introduce another layer of complexity to sterilization protocols. The heat tolerance of various plastics can significantly vary, influencing how these materials interact with heat. Some plastics may deform or leach harmful substances if exposed to high temperatures during sterilization. This necessitates the use of tailored thermal processing solutions by Thermosoft Technologies that account for the specific type of plastic, thereby safeguarding food safety without compromising the integrity of the packaging.

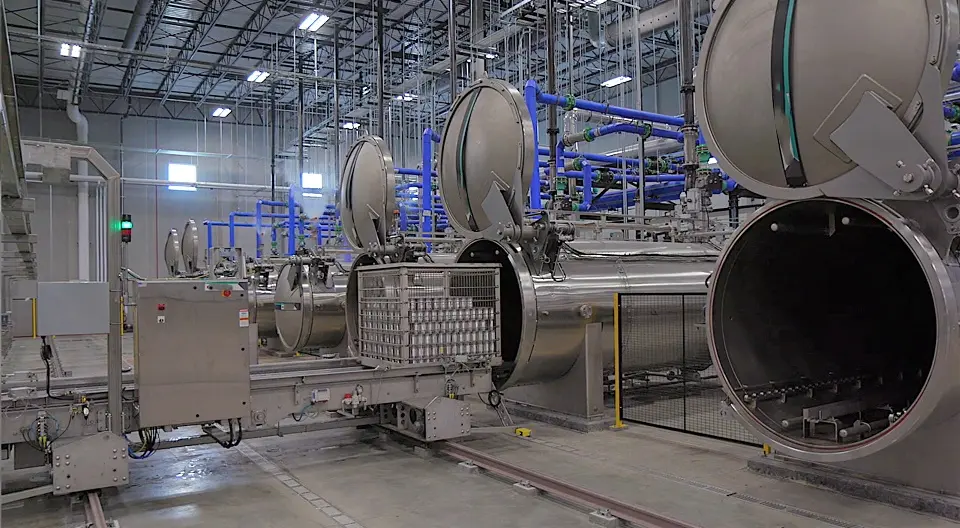

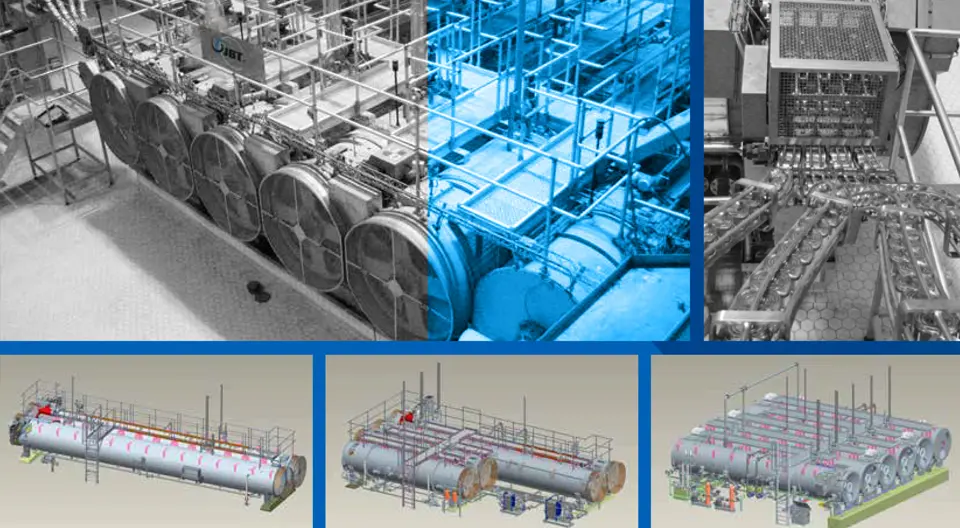

TST offers Retort Qualification & Retort Validation, including Temperature Distribution, Heat Distribution, and Heat Penetration Studies.

Thermal non‐uniformity is a concern that can result in cold spots, which lower the microbiological safety of the product. The purpose of TD study is to determine the area within the retort chamber that has the minimum (coldest) temperature during the normal cycle. Simply to find the slowest heating location inside the retort vessel. Anything that is placed in this area will be the last to reach the sterilization temperature. This “cold spot” area or “slowest heating location” will be where future heat penetration tests should be undertaken in the retort. Thus Temperature Distribution Study describes a series of temperature measurements at different pack locations inside a retort, to assess the temperature uniformity and stability through the system and identify the ‘cold spot’ position inside the retort.

Heat distribution refers to the delivery of heat by retort sterilizer to the product area. The Temperature Distribution testing usually focuses on come-up and holding portions of the retort cycle. Temperature uniformity during come-up and holding phase of the retort process may not always correlate to adequate heat transfer into the product filled containers throughout the retort, hence the need for Heat Transfer Distribution studies. Here we calculate the heating rate at different positions within the retort. Heat distribution becomes more meaningful than temperature distribution when the rate of heat transfer is affected by process variables such as the water flow rate or ventilation fan speed, for example in water or steam/air retorts respectively. It is specifically required when exporting low acid sterilized product processed using these retort types to the US market.

The purpose of a heat penetration study is to monitor the rate of temperature change in the food inside the container as it is heated in a specific retort system. The temperature sensor, or a thermocouple, is located inside the product at the slowest heating location (cold spot) of the container. Finally, this heat penetration data is used to mathematically define the heating rate. Thus, the heating and cooling behavior of a product packed and hermetically sealed inside a container and processed in a specific retort system can be established for safe thermal processes and evaluating process deviations. This also helps find the cold spot in the product/container and ensures all products receive the minimum thermal process to deliver a safe product.

A temperature distribution test and heat distribution test should be completed before commencing the heat penetration test. The goal of these studies is to identify the worst-case temperature response expected in commercial production, as influenced by the product, package, and process.

Retort sterilization is a fundamental process in the food processing industry, primarily designed to extend the shelf life of canned and packaged foods while ensuring safety for consumer consumption

Modern technologies can improve food safety and product quality, with insights into the recommended practices for achieving regulatory compliance in food processing operations.

Effective cooling preserves product quality and safety, the stages of qualification, and tailored solutions for monitoring temperature control.

Explores the critical requirements for validating smoke houses, emphasizing the importance of compliance with USDA and FDA standards

Hydrostatic retorts, are essential devices for ensuring food product safety through effective sterilization methods involving high pressure and temperature.

Which Type of Retorting System Is Best Suited for Your Containers and Products? such as water immersion, water cascade, steam/air processing, and steam/water spray processing.

At TST, we offer advanced process authority and validation services in support of thermally processed shelf-stable food products. Our teams are industry experts and come well-equipped with industry-leading thermal validation equipment