Thermal processing, specifically a technique known as commercial sterilization, is a critical step in ensuring the safety and shelf-stability of many food products. This process involves the controlled application of a lethal amount of high heat, precisely calculated to effectively eliminate spoilage and pathogenic microorganisms. Among the most formidable of these organisms is Clostridium botulinum, a bacterium whose non-vegetative spores exhibit exceptional resistance to elevated temperatures. The inherent danger associated with this pathogen—namely, its ability to produce potent neurotoxins—necessitates an exceptionally rigorous approach to thermal processing. To guarantee that commercial sterilization is achieved with absolute certainty and to mitigate the severe public health risks posed by under-processed products, two fundamental protocols are meticulously performed by specialized Thermal Process Authorities and skilled thermal process technicians. These protocols are not merely quality checks; they are indispensable validation steps crucial for assuring that a shelf-stable, low-acid food product is unequivocally safe for both human and animal consumption.

This discussion will delve into an in-depth examination of these two vital testing methodologies. We will explore the sophisticated types of hardware and software that empower process authorities, thermal process technicians, and food scientists to accurately validate retort performance, precisely verify thermal processes, and effectively develop robust formulations for a wide array of shelf-stable, low-acid food products. These advanced tools are at the forefront of preventing foodborne illnesses and upholding the integrity of the food supply chain.

The Temperature Distribution (TD) study also called as the retort validation is a critical evaluation method employed in the thermal processing of food products to ensure uniform heat distribution and effective sterilization within a retort. At its core, the TD Study serves a dual purpose: it precisely determines the duration required for a retort to attain a pre-defined processing temperature, and, perhaps even more crucially, it meticulously assesses the homogeneity of the heating medium (be it steam, water, or a combination) as it circulates throughout the retort, especially when loaded with product.

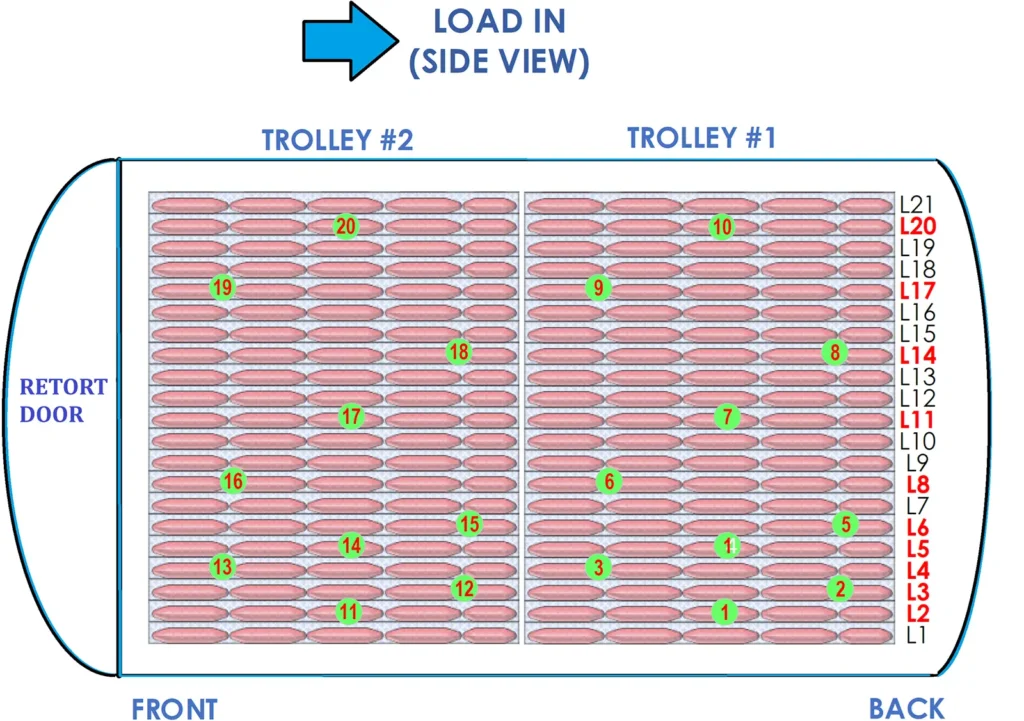

To execute a TD test, a strategic number of temperature dataloggers —highly sensitive temperature-measuring devices—are carefully positioned within a ballast load. This ballast load is not merely a placeholder; it typically consists of bentonite solution -filled containers specifically chosen to mimic the most challenging or “densest” product load that will routinely be processed within that particular retort. The size and configuration of the retort directly influence the number of temperature loggers required to achieve adequate coverage.

The strategic placement of these temperature probes within the ballast load is a meticulous process, guided by several factors. These factors include, but are not limited to, the specific type of thermal process being validated (e.g., still retort, rotary retort), and crucially, the method of agitation if one is employed (e.g., end-over-end, or horizontal agitation). The goal is to capture temperature readings from various locations, including areas that are historically challenging to heat uniformly.

Regardless of the precise placement strategy, a fundamental principle of TD testing is that the more data points that are recorded, the greater the accuracy in identifying the retort’s cold spot. The cold spot is the location within the retort that heats up the slowest, and therefore, represents the critical point for ensuring that the entire batch of product receives the minimum required thermal treatment for commercial sterility. By precisely mapping the temperature distribution and identifying this cold spot, thermal process authorities can then design and validate thermal processes that guarantee the destruction of even the most heat-resistant microorganisms, safeguarding public health.

The Heat Penetration (HP) Study is a critical experimental procedure conducted on a particular food product and its retortable container. Its primary objective is to precisely determine the time-temperature profile necessary for the product-container combination to achieve a predetermined level of microbial lethality during thermal processing. Just as with the Temperature Distribution (TD) test, accurately identifying the cold spot within the container—the slowest heating zone—is paramount in HP testing.

A wide range of factors related to both the product and the container can significantly influence how heat penetrates the hermetically sealed product. Therefore, meticulous consideration of these attributes is essential when performing HP studies. The transfer of heat into the container and throughout its contents occurs through two primary mechanisms: conduction and convection.

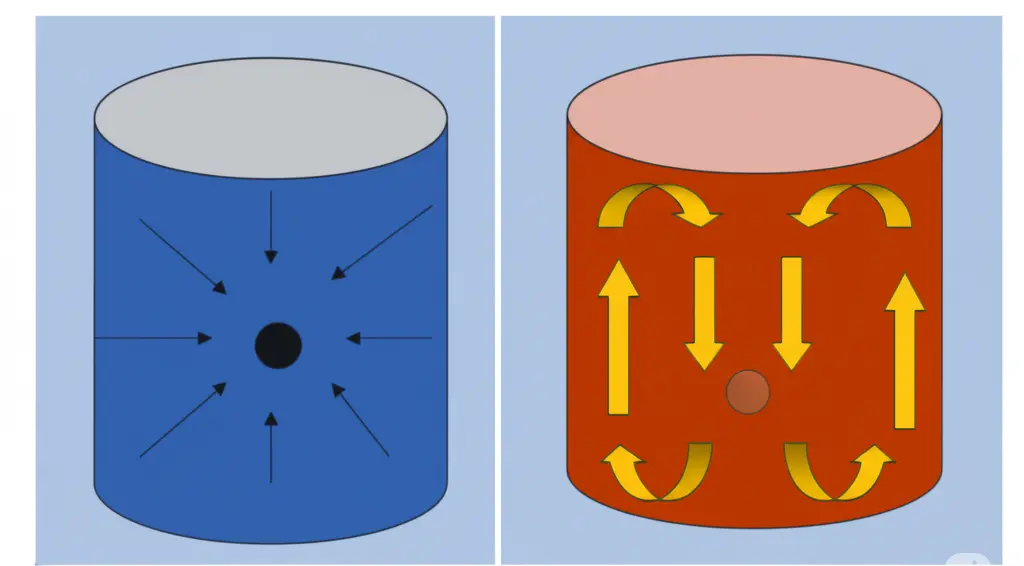

Conduction refers to the gradual transfer of heat through the product from the outer surfaces of the container towards the geometric center or the point representing the highest horizontal and vertical cross-section. This mode of heat transfer is typically slower and more reliant on the thermal conductivity of the product itself.

Convection, on the other hand, occurs primarily in liquid-based products. As the container is heated, the liquid near the hotter container walls becomes less dense and rises, while the cooler, denser liquid in the center descends, creating a circulating current. This upward flow along the container wall and downward flow along the central vertical axis facilitates a more rapid heat transfer compared to conduction alone.

The following is a partial list of key product attributes that have a direct impact on the rate and extent of heat penetration:

In the context of static retort processing, the mode of heat transfer is fundamentally dictated by the product’s physical properties.

Conduction heating is the dominant mechanism in high-viscosity or high-consistency products. This occurs when heat slowly transfers from particle to particle, a common characteristic of thick, non-flowing foods. Excellent examples include refried beans, dense vegetable and fruit purees.

Conversely, convection heating is the primary method of heat transfer in low-viscosity or low-consistency products. Here, the heat is transferred much more rapidly through the movement of the liquid itself. This is seen in products like clear broths and ready-to-drink beverages, where heated liquid at the container walls rises, and cooler liquid from the centre sinks, creating a continuous flow.

To accurately classify a product’s viscosity and predict its heating behavior, three types of specialized instruments are used:

Furthermore, a combination of both conduction and convection heating occurs in products containing both solid particulates and a liquid component, such as vegetables suspended in a brine solution. In these instances, the liquid heats via convection, while the solid particulates heat via the slower process of conduction. For validation, it is critical that the temperature probe be inserted into the largest foreseeable particulate and positioned in the container’s cold spot to ensure that the slowest-heating portion of the product reaches the target temperature.

The use of retort agitation methods can dramatically improve heat penetration. Techniques like end-over-end & axial rotation or horizontal reciprocation (e.g., Gentle Motion™ and SHAKA™) introduce forced convection by physically stirring the product within its sealed container. This agitation allows for a significantly more homogeneous distribution of heat, drastically reducing processing times. With forced convection, even products that are highly susceptible to over-processing and degradation from prolonged high heat exposure can be successfully and safely commercially sterilized.

However, a crucial consideration when using agitation is ensuring the integrity of the heat penetration test itself. Special care must be taken to prevent the temperature probe from becoming dislodged from the particulate it is impaling during the vigorous motion, as this would invalidate the test results.

The choice of temperature measuring devices for thermal process evaluations varies as per the type of retorts, containers, and food products they are used to validate. While a variety of thermocouples or data loggers exist, the Type-T thermocouple is the industry standard due to its exceptional accuracy and stability within the critical temperature range of commercial sterilization. For data acquisition, both wired and wireless temperature dataloggers are employed in Heat Penetration (HP) and Temperature Distribution (TD) testing, each with distinct advantages. Companies like Ellab, TMI-Orion manufactures these high end temperature data logging system.

For data acquisition, both wired and wireless temperature dataloggers are employed in Heat Penetration (HP) and Temperature Distribution (TD) testing, each with distinct advantages.

Furthermore, different types of retortable containers—from metal cans and glass jars to flexible pouches and plastic trays—necessitate their own specialized probing methods to ensure the temperature sensor is correctly positioned at the cold spot for accurate data collection.

Because of the potentially catastrophic public health risks associated with under-processed foods and beverages, regulatory oversight is stringent. The United States Food and Drug Administration (FDA), the Department of Agriculture (USDA), and other reputable food regulatory agencies worldwide mandate that every retort used for processing shelf-stable, low-acid food or nutraceutical products must undergo a Temperature Distribution (TD) Study. This rigorous testing is a non-negotiable prerequisite to ensure the equipment itself is capable of delivering uniform heat. Likewise, every single batch of a low-acid product that reaches consumers has undergone extensive Heat Penetration (HP) testing. This validation confirms that the specific product and container combination reaches the required thermal lethality.

In summary, retort validation through comprehensive TD studies and in-container HP testing during product development are two indispensable tools. They are the backbone of food safety, providing human food, pet food, beverage, and nutraceutical manufacturers with the data they need to ensure their low-acid products are safe for consumption. When properly processed and stored, these products do not require refrigeration and can enjoy a long shelf life of months, if not multiple years.

At TST, we offer advanced process authority and validation services in support of thermally processed shelf-stable food products. Our teams are industry experts and come well-equipped with industry-leading thermal validation equipment