Why Thermal Process Validation is Crucial for Canned Food Manufacturers? Canned foods are a convenient and long-lasting option for consumers,...

Pasteurization tunnels are key components in the food and beverage processing industry, designed to reduce the microbial load of products, thereby increasing their safety and extending shelf life. These tunnels operate based on the principle of heat transfer, wherein products such as liquids, sauces, and ready-to-eat foods pass through a controlled environment that employs either hot water or steam to achieve the desired reduction in harmful microorganisms. By systematically exposing products to these heat treatments, pasteurization tunnels ensure that a wide array of pathogens, including bacteria and viruses, are effectively eliminated.

The functionality of pasteurization tunnels can be categorized into several stages, including pre-heating, pasteurization, and cooling. Initially, products are pre-heated to prepare them for the main pasteurization process. The core phase involves maintaining precise temperature and time intervals, as specified by regulatory guidelines, to ensure that microbial agents are targeted effectively. Following this, a cooling phase is essential to bring the temperature down rapidly to preserve product quality and prevent any potential spoilage. Each stage of this process is critical for the overall efficacy of pasteurization.

Different types of pasteurization processes are employed depending on the specific requirements of the product being treated. For instance, hot water pasteurization is commonly used for bottled beverages, while steam pasteurization is particularly effective for products with high solids content. The choice of method often hinges on factors such as the nature of the food item, packaging requirements, and regulatory standards. Understanding these distinctions is vital for ensuring that pasteurization processes are validated and qualified. Such validations are necessary to maintain compliance with food safety standards and to guarantee that the processes effectively reduce the risk of foodborne illnesses.

Qualification of pasteurization tunnels is an essential process that ensures food products are treated effectively to prevent microbial contamination while maintaining product quality. To achieve compliance with regulatory standards, companies must familiarize themselves with the guiding principles set forth by bodies such as the Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These regulations dictate the operational specifications that pasteurization systems must meet, including temperature requirements, processing times, and end-product microbiological criteria.

Thermal mapping is a vital step in the qualification process. It involves a thorough assessment of the thermal distribution within the pasteurization tunnel and helps identify any cold spots that may affect the efficacy of the heat treatment. By using validated instrumentation and techniques, businesses can collect and analyze temperature data throughout the entire system. This mapping ensures that all areas of the product receive adequate exposure to the required heat, thereby guaranteeing the safety and quality of the pasteurized food items.

Documentation plays a critical role in ensuring compliance with qualification requirements. Accurate and detailed records of the qualification protocols, results of thermal mapping, and maintenance activities must be maintained. Proper documentation allows for traceability and serves as evidence during regulatory inspections or audits. Adherence to Good Manufacturing Practices (GMPs) is equally important. Companies should establish standard operating procedures (SOPs) that encompass preventive maintenance, staff training, and regular equipment calibration to ensure optimal performance of the pasteurization tunnels.

To prepare their systems for qualification, businesses should conduct a comprehensive review of their processes, align their operations with recognized standards, and implement adequate preventive measures. This proactive approach not only enhances safety and compliance but also fosters overall operational efficiency.

The validation of pasteurization tunnels is a critical process that ensures food safety and quality; however, it is fraught with a variety of challenges that can complicate the validation outcomes. One of the predominant issues is the variability in product load. Different products may require different pasteurization times and temperatures, leading to discrepancies in the validation process. This variability necessitates a thorough understanding of how different loads interact with the heating and cooling processes within the tunnel, which might lead to inconsistent results if not properly managed.

Another significant challenge is equipment drift. As machinery operates over time, physical components may wear down or misalign, affecting the efficacy of the pasteurization process. Such changes can result in deviations from the originally validated parameters, thereby necessitating regular recalibration and validation of the equipment to maintain the required standards. Without routine checks, operators may unknowingly process products that do not meet safety criteria.

Environmental conditions also play a crucial role in the validation process. External factors such as room temperature, humidity, and airflow can influence the performance of the pasteurization tunnel, leading to variations in heat transfer and other critical parameters. These environmental influences must be taken into account when conducting validation studies to ascertain that the process remains effective under varying conditions.

To address these challenges, employing modern technologies for monitoring and process control can significantly enhance the reliability of validation studies. Implementing real-time monitoring systems to track temperature and flow rates allows for immediate adjustments and data collection, improving consistency. Moreover, establishing best practices, such as conducting thorough risk assessments and utilizing standardized protocols for validation studies, can ensure more reliable outcomes. These solutions, when integrated effectively, contribute to an overall improved validation process in pasteurization tunnels.

The efficient qualification and validation of pasteurization tunnels is crucial for ensuring product safety and regulatory compliance in food processing industries. TST offers a comprehensive range of solutions designed to optimize performance and enhance the reliability of pasteurization processes. Among the most effective solutions are validation services that include thorough assessments and documentation tailored to meet specific regulatory standards. These services ensure that every component of the pasteurization tunnel operates within its intended parameters, thus safeguarding product quality.

In addition to validation services, TST provides an array of monitoring and control systems. These technologies are integrated into pasteurization tunnels to continuously track temperature, flow rates, and pressure. By employing advanced data analytics, these systems not only enhance operational efficiency but also allow for timely interventions, should any irregularity arise during the pasteurization process. This proactive approach serves to significantly reduce the risk of product contamination, a critical concern in food safety.

Furthermore, TST’s selection of specialized equipment, such as heat exchangers and thermal profiling tools, are designed to cater to varying pasteurization needs across different processing environments. Each piece of equipment is engineered for optimal thermal efficiency, ensuring that food products are pasteurized uniformly and effectively. Client testimonials highlight instances where the implementation of TST solutions led to measurable improvements in production efficiency and product quality, showcasing the tangible benefits of their offerings.

In choosing the right combination of TST products and services, clients can streamline their pasteurization processes, enhance safety, and stay compliant with industry standards. These solutions not only address present needs but also equip operations for future advancements in pasteurization technology, ensuring sustained success in food production.

Why Thermal Process Validation is Crucial for Canned Food Manufacturers? Canned foods are a convenient and long-lasting option for consumers,...

Navigating FDA Regulations: FCE Registration and SID Filings It is widely known in the canning industry that the U.S. Food...

Thermal Process Validation – Hot Fill & Hold July 6, 2025 The Hot-Fill-Hold method is a crucial processing technique specifically...

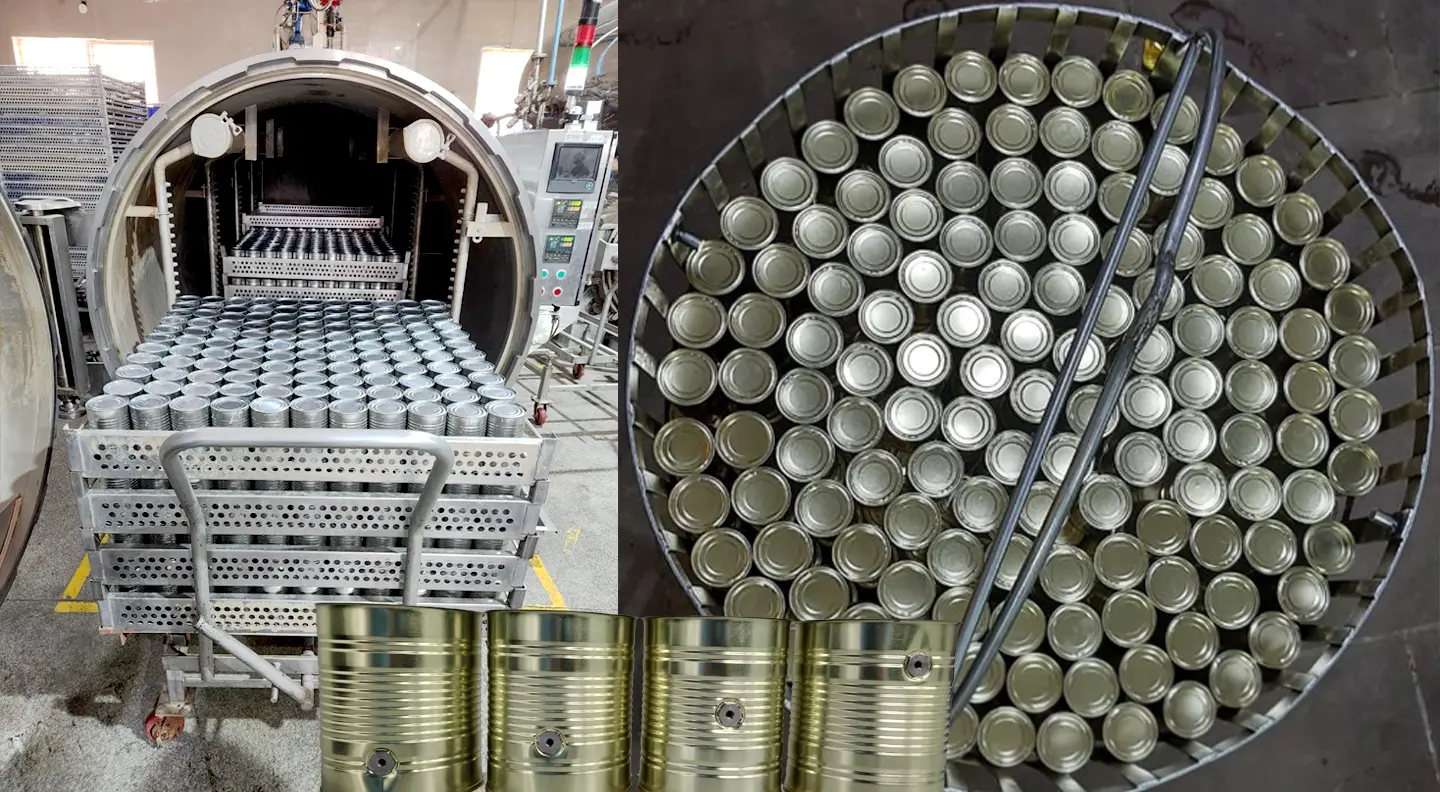

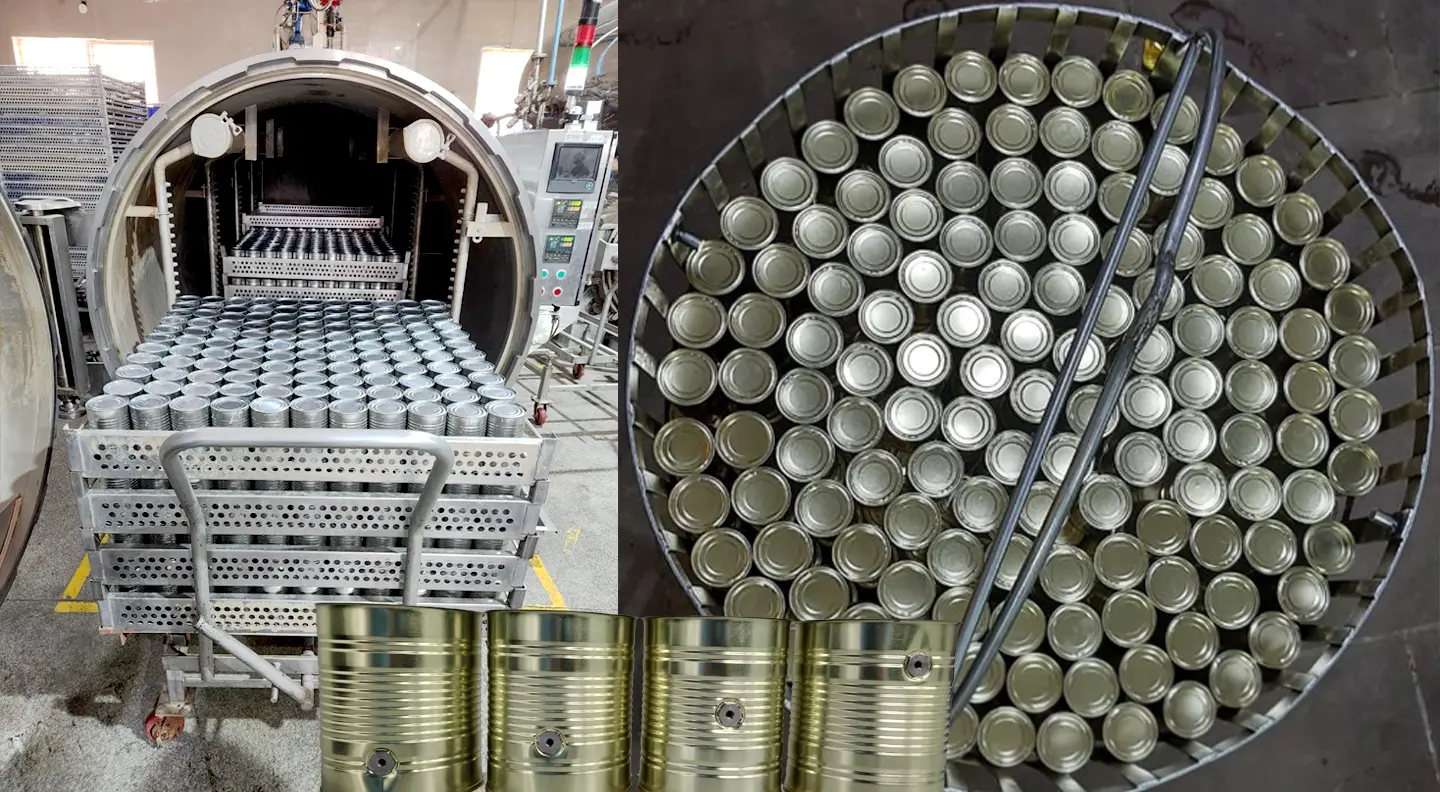

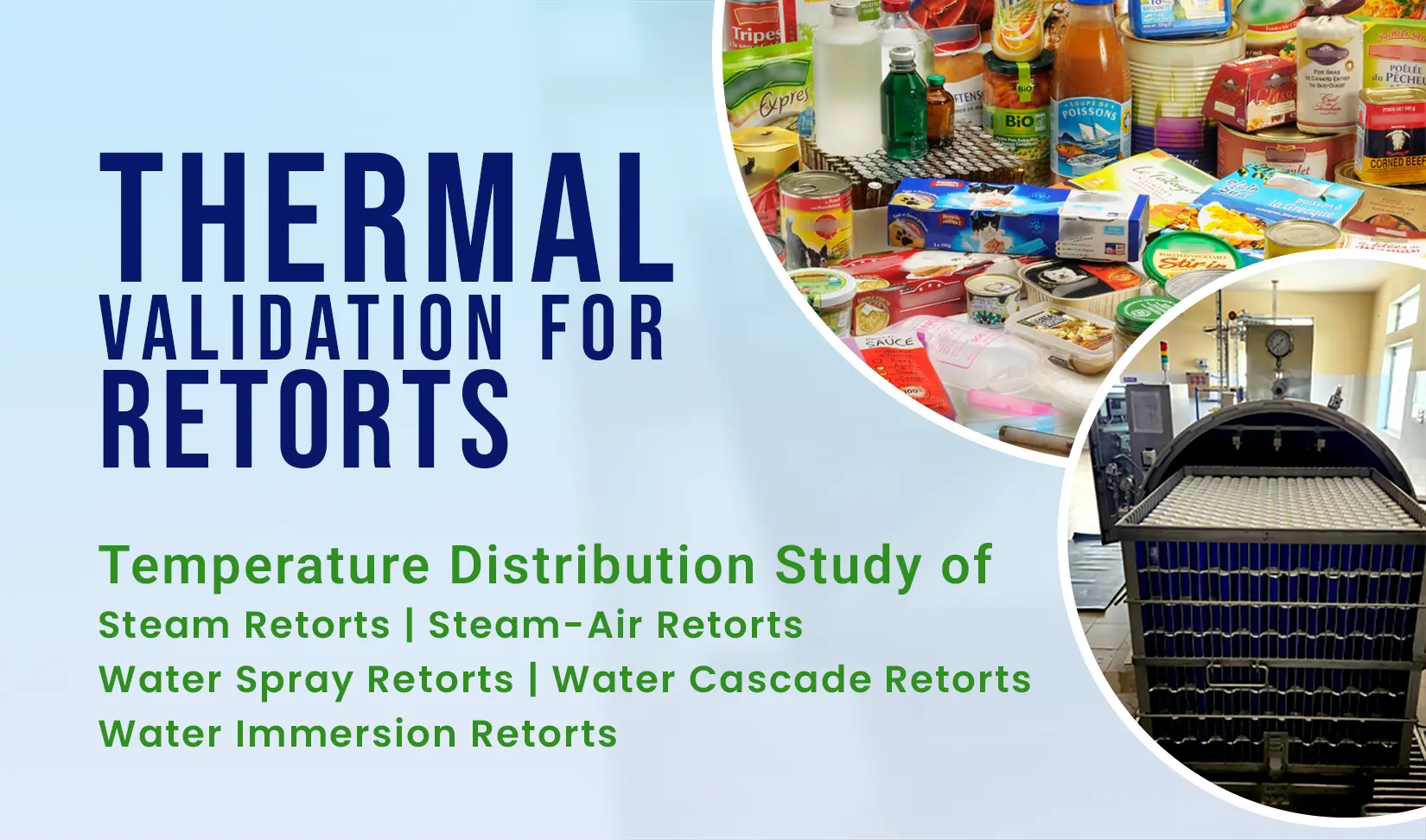

Retort Temperature Distribution Study and Product Heat Penetration Study Thermal processing, specifically a technique known as commercial sterilization, is a...

Thermal Process Authority in India Thermosoft Technologies has established itself as a leading thermal process authority in India, known for...

How to Ensure a Smooth Food and Beverage Sterilization Process? Ensuring a smooth food and beverage sterilization process is critical...

Ultimate Challenge in Retort Process: Finding the Balance between Food Safety & Quality For low-acid foods packed in the hermetically...

In-Container Sterilization – Ensuring Commercial Sterilization Through Critical Factors as per USFDA Guidelines Introduction:The term “Commercial Sterilization” refers to a...

Thermal validation is a crucial aspect of food processing that involves determining the effectiveness of heat treatment methods, particularly in...

At TST, we offer advanced process authority and validation services in support of thermally processed shelf-stable food products. Our teams are industry experts and come well-equipped with industry-leading thermal validation equipment