Why Thermal Process Validation is Crucial for Canned Food Manufacturers? Canned foods are a convenient and long-lasting option for consumers,...

Cooker cooler qualification and validation often require tailored solutions to ensure complete adherence to safety and efficacy standards in food processing environments. TST provides a comprehensive suite of solutions aimed at addressing these specific qualification and validation needs. Each solution is designed to enhance operational efficiency while maintaining the integrity of products.

One of the cornerstone offerings is temperature mapping software. This tool enables users to gather critical temperature data throughout various stages of the cooking and cooling processes. User-friendly and accurate, the software allows for real-time monitoring and reporting, identifying potential deviations in temperature control that could compromise food safety. The advantage of this software is its ability to facilitate compliance with regulatory standards, thus protecting your business from potential penalties.

Another key solution is the integration of advanced data loggers. These devices serve to collect temperature and humidity data automatically throughout the cooking and cooling phases. By employing data loggers, facilities can minimize human error associated with manual readings while ensuring a reliable record for audits. Data loggers can also be configured to send alerts if thresholds are breached, enabling timely interventions that safeguard product quality.

TST also offers meticulously crafted validation protocols tailored to suit various operational needs. These protocols guide businesses in conducting thorough checks on their cooker cooler systems, covering parameters such as thermal profiling and performance testing. By adhering to these protocols, organizations can ensure their systems are operating effectively, thereby mitigating risks related to food safety.

In addition to these innovative solutions, TST shares success stories that highlight the effectiveness of their tools. Many clients have reported significant improvements in compliance rates and operational efficiencies after implementing TST’s recommended solutions. Thus, the range of services offered not only aids compliance but also enhances overall process efficacy in cooker cooler systems.

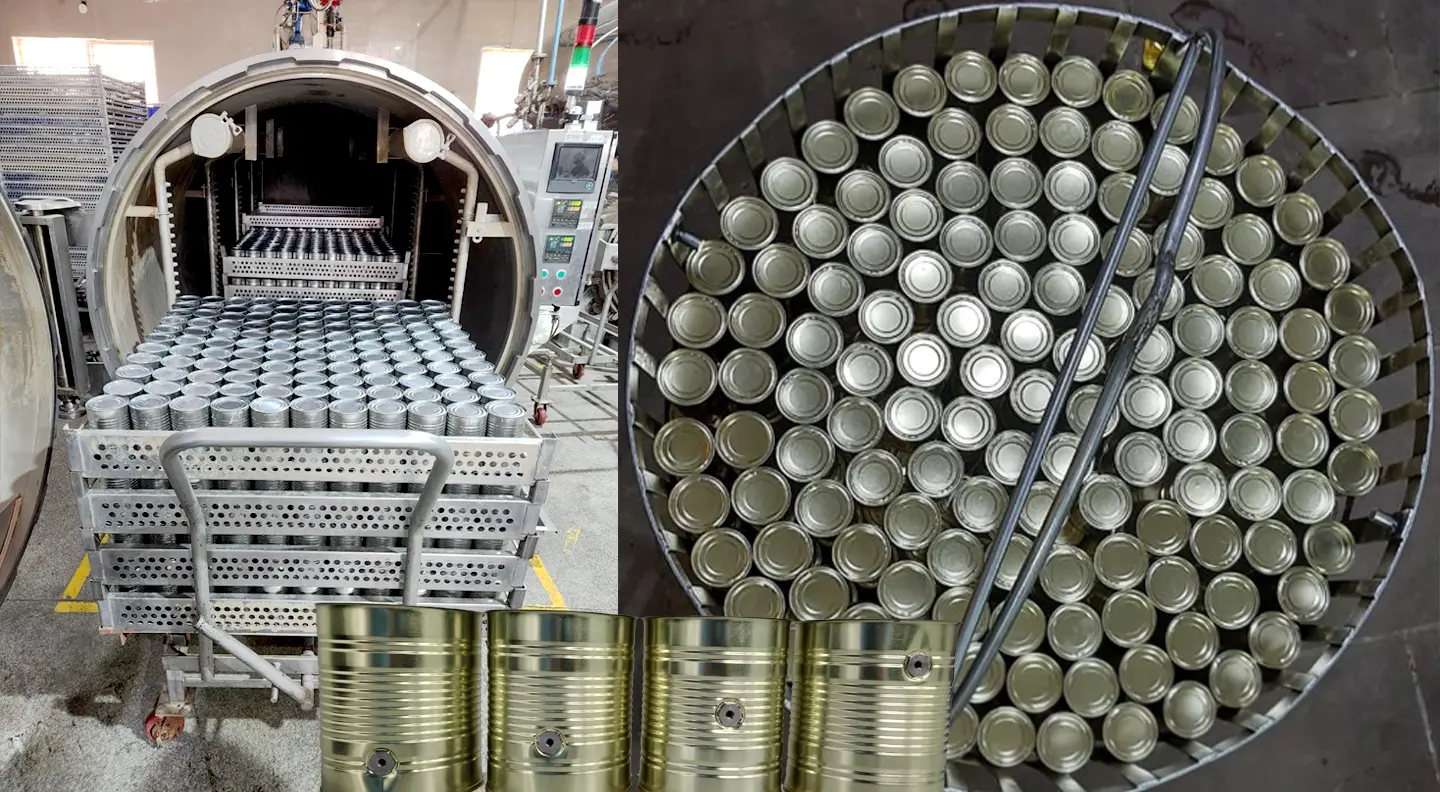

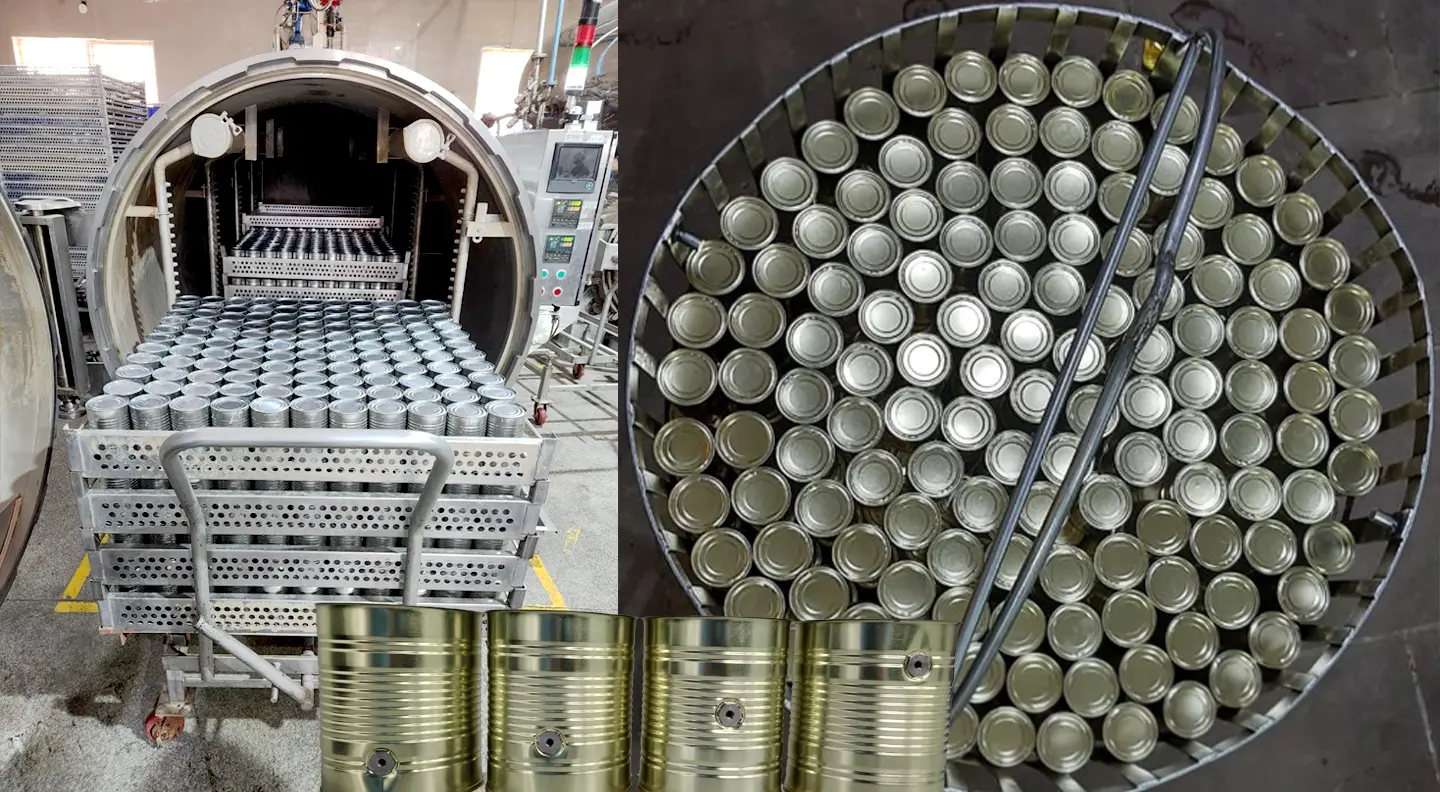

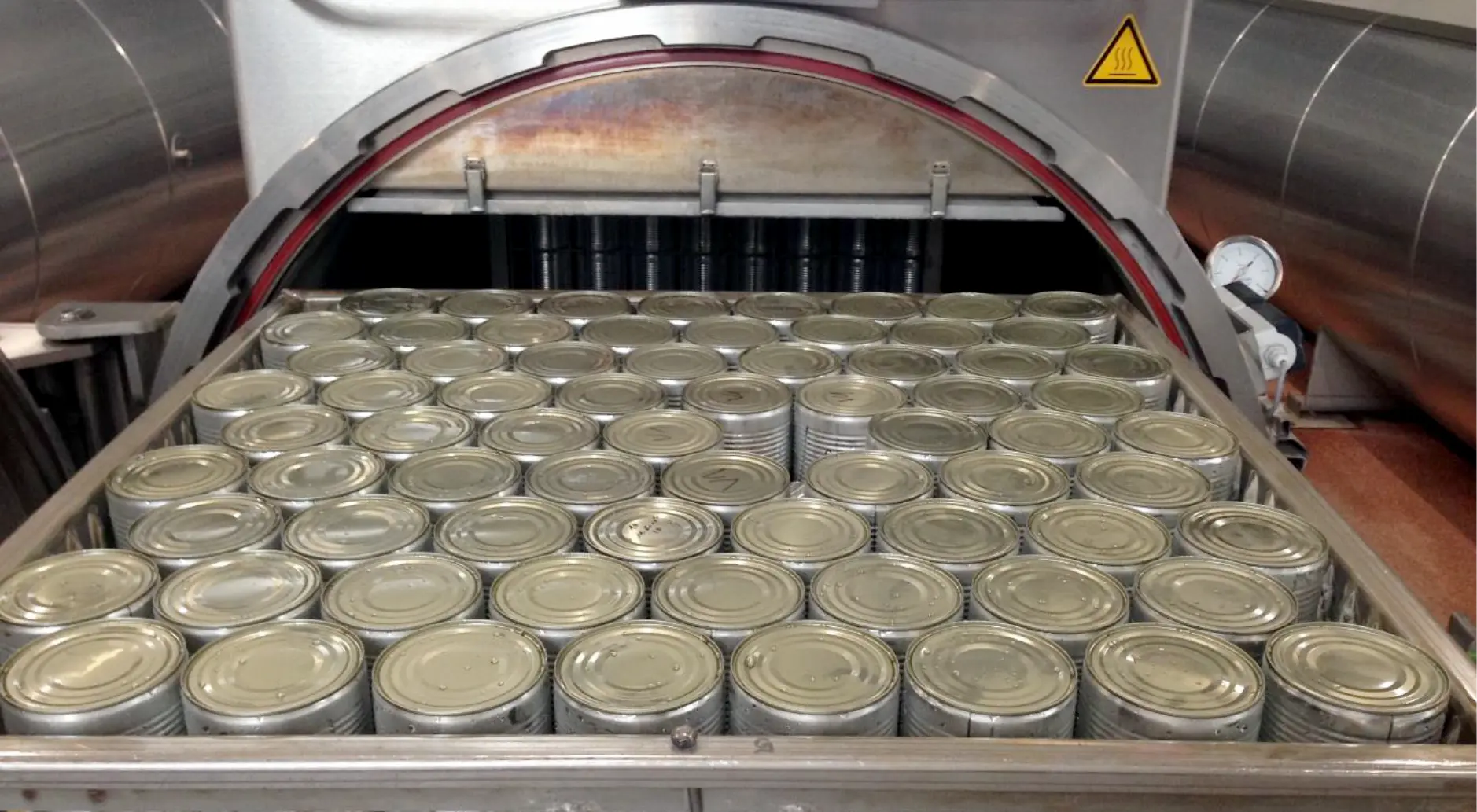

The sterilization of closed cans is a crucial procedure in food processing, ensuring safety and extending shelf life. This process begins as cans enter the sterilizer directly from the closing machine, minimizing waiting time. Such efficiency is vital in a competitive market, as it reduces operational bottlenecks.

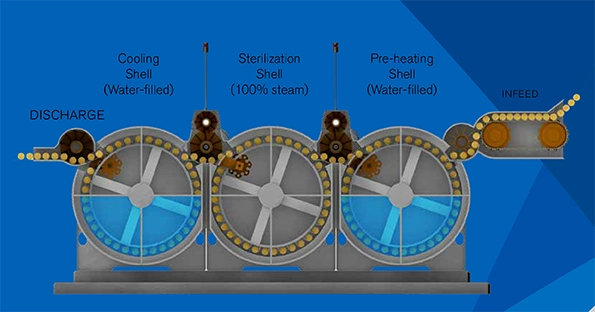

A feed device plays a significant role in this operation, delivering the cans into the revolving reel of the first vessel efficiently. The interaction between this reel and a stationary spiral advances each can through the vessel, ensuring no can remains stagnant. The continuous spiraling motion, paired with the rotation of the container within the vessel, guarantees uniform heat distribution, enabling an even cook for every container.

One of the standout features of this system is that every can is treated individually, receiving the same thermal process regardless of its position in the sterilizer. After cooking, the cans are transferred to a water-filled cooling vessel where a similar process ensures they cool down efficiently. This method is designed to uphold the quality of the product while ensuring safety standards are met.

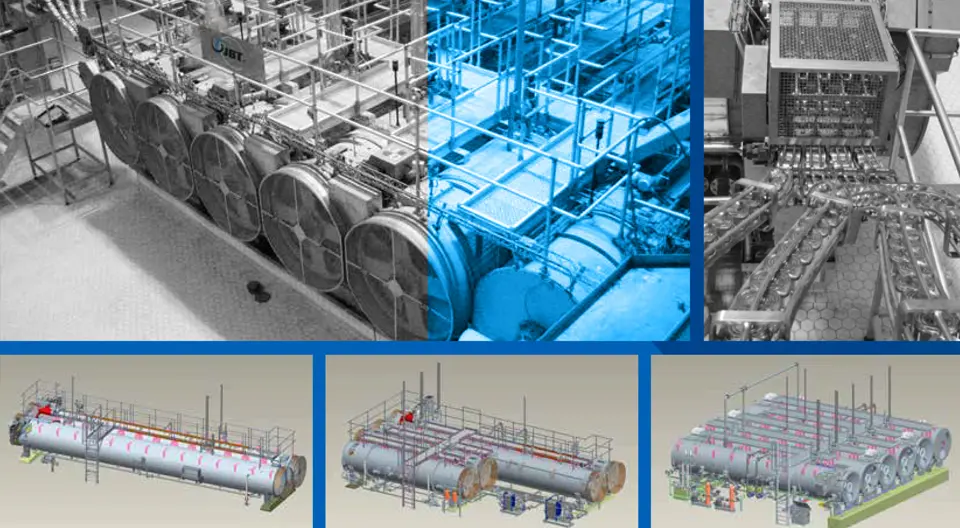

Continuous rotary pressure sterilizers are revolutionary machines designed to enhance the efficiency of cooking and cooling processes in food preservation. Unlike traditional methods, these sterilizers utilize a continuous operation model that allows for greater automation, ultimately optimizing production timelines in food manufacturing environments.

These sterilizers incorporate a unique design that allows the can to undergo a 3-phase movement cycle for each turn of the reel. This intermittent axial agitation not only facilitates convection heating but also results in significant time savings during the cooking and cooling stages. By swiftly and evenly distributing heat, continuous rotary pressure sterilizers ensure that food products are cooked thoroughly while minimizing the risk of spoilage.

One notable advantage of these machines is their ability to achieve high-temperature cooking for short periods of time, coupled with rapid cooling. This efficiency in processing leads to improved product quality and less energy consumption. As food manufacturers continue to seek methods for sustainable and economical production, continuous rotary pressure sterilizers stand out as a trustworthy solution that not only meets operational needs but also supports food safety standards.

In today’s competitive market, product uniformity is crucial for ensuring high quality and safety in food manufacturing. This blog post explores the importance of consistent processing methods and quality assurance practices that guarantee every product delivers the same taste, nutrients, and appearance. By implementing standardized thermal processes, manufacturers can maintain integrity, meet safety guidelines, and foster consumer trust. Learn how reliable product uniformity benefits both health-conscious consumers and brand reputation in the crowded market.

Why Thermal Process Validation is Crucial for Canned Food Manufacturers? Canned foods are a convenient and long-lasting option for consumers,...

Navigating FDA Regulations: FCE Registration and SID Filings It is widely known in the canning industry that the U.S. Food...

Thermal Process Validation – Hot Fill & Hold July 6, 2025 The Hot-Fill-Hold method is a crucial processing technique specifically...

Retort Temperature Distribution Study and Product Heat Penetration Study Thermal processing, specifically a technique known as commercial sterilization, is a...

Thermal Process Authority in India Thermosoft Technologies has established itself as a leading thermal process authority in India, known for...

How to Ensure a Smooth Food and Beverage Sterilization Process? Ensuring a smooth food and beverage sterilization process is critical...

Ultimate Challenge in Retort Process: Finding the Balance between Food Safety & Quality For low-acid foods packed in the hermetically...

In-Container Sterilization – Ensuring Commercial Sterilization Through Critical Factors as per USFDA Guidelines Introduction:The term “Commercial Sterilization” refers to a...

Thermal validation is a crucial aspect of food processing that involves determining the effectiveness of heat treatment methods, particularly in...

At TST, we offer advanced process authority and validation services in support of thermally processed shelf-stable food products. Our teams are industry experts and come well-equipped with industry-leading thermal validation equipment