Why Thermal Process Validation is Crucial for Canned Food Manufacturers? Canned foods are a convenient and long-lasting option for consumers,...

In the realm of food processing and preservation, smoke houses play a crucial role in imparting flavor and ensuring safety. However, to achieve effective validation of smoke houses, it is imperative to understand the specific requirements set forth by regulatory bodies. Prominent organizations such as the United States Department of Agriculture (USDA) and the Food and Drug Administration (FDA) establish the standards that must be adhered to for proper smoke house operations.

The guidelines mandated by these agencies may vary depending on the type of smoke house being utilized, whether it is a traditional kiln or a more modern, automated system. Each variety of smoke house requires tailored protocols to meet necessary food safety and quality benchmarks. For instance, the requirements for hot smoking may differ significantly from those for cold smoking, leading to distinct temperature control and smoke concentration standards that must be respected during the validation process.

Maintaining compliance with these regulations is not only vital for ensuring food safety but also contributes to operational efficiency within your smoke house. Regulatory compliance ensures that the processes in place effectively eliminate pathogenic microorganisms, thereby mitigating health risks associated with improperly processed food products. Key parameters for evaluation during the validation process include temperature control, smoke concentration levels, and humidity regulations. Each of these factors significantly influences the safety and quality of the finished products.

In summary, the validation of smoke houses is a multifaceted process governed by specific requirements established by regulatory agencies. Understanding these requirements, along with the critical evaluation parameters, is essential for achieving compliance and ensuring the safety of food products processed in smoke houses. Proper validation not only adheres to legal standards but also enhances the overall integrity of the food supply chain.

TST offers a comprehensive range of solutions designed to facilitate effective smoke house qualification and validation, specifically tailored to meet the diverse needs of various smoke house configurations. One of the key offerings is the “TST Validation Kit,” which includes a complete set of tools and instruments essential for performing thorough assessments. This kit not only simplifies the validation process but also ensures accuracy and reliability in data collection, helping companies to achieve compliance with industry standards efficiently.

Another noteworthy solution is the “TST Monitoring System,” which employs advanced technology to continuously track and report on critical parameters within the smoke house environment. This real-time monitoring capability allows operators to swiftly identify deviations from standard operating conditions, ensuring that product quality and safety are upheld. Moreover, the system is user-friendly and can be integrated seamlessly with existing operational frameworks, enhancing overall operational efficiency.

For establishments facing challenges in documentation and record-keeping, TST provides a comprehensive “Validation Documentation Package.” This package includes templates and guidelines for generating the necessary documentation, which is crucial for demonstrating compliance during audits. With this solution, businesses can streamline their validation processes while maintaining detailed records, ultimately reducing the risk of non-compliance.

Furthermore, TST’s solutions have been effectively applied in various real-world scenarios. For instance, a recent case study highlighted how a manufacturer leveraging the TST Validation Kit improved their validation times by 40%, leading to a faster time-to-market for their products. These success stories underline the effectiveness of TST’s solutions in optimizing smoke house qualification and validation processes, ensuring businesses remain compliant while enhancing productivity.

The validation process for smoke houses presents several challenges that operators must address to ensure compliance with industry standards. One of the primary difficulties lies in achieving and maintaining consistent temperature and humidity levels throughout the smoking process. Fluctuations in these parameters can lead to variations in the final product, potentially compromising food safety and quality. Smoke house operators often find it challenging to calibrate equipment precisely, which can result in discrepancies between documented settings and actual performance.

Documenting compliance also poses significant challenges for smoke house operators. The regulatory landscape requires detailed records of the smoking process, including temperature logs, humidity readings, and equipment maintenance schedules. Inadequate documentation can lead to non-compliance issues and a lack of trust in the process. It is essential that operators maintain thorough and accurate records while ensuring that all staff are trained on the required documentation protocols.

Furthermore, there may be discrepancies between the theoretical operational settings of the smoke house and the actual outcomes observed during production. Equipment malfunctions or human error can contribute to these inconsistencies, making it vital for operators to implement reliable monitoring systems. Regular equipment checks should be part of an operator’s routine to ensure that all machinery is functioning as intended and that no adjustments are necessary to meet compliance standards.

To overcome these challenges, smoke houses should prioritize comprehensive training programs for their staff to enhance their understanding of the equipment and compliance requirements. Additionally, embracing technology such as automated monitoring systems can aid in maintaining ideal conditions within the smoke house. Proactive management, including routine inspections and adjustments, is critical to ensuring that both temperature and humidity levels remain stable throughout the smoking process, ultimately facilitating successful validation.

The landscape of smoke house qualification and validation is rapidly evolving, driven by advancements in technology and shifting industry priorities. One notable trend is the increasing adoption of monitoring and control technologies. These innovations, such as real-time temperature and humidity sensors, enable operators to ensure optimal conditions within smoke houses with greater accuracy. As these technologies become more sophisticated, they allow for more precise control over the smoking process, thus enhancing product quality and consistency.

Alongside these monitoring improvements, data analytics is emerging as a powerful tool in smoke house qualification. By leveraging big data, operators can analyze historical performance data to identify patterns and anomalies that may affect product quality. Enhanced analytics enable operators to make informed decisions based on predictive modeling, facilitating proactive adjustments during the smoking process. This shift from reactive to proactive management not only improves operational efficiency but also strengthens compliance with food safety regulations.

Regulatory changes also play a crucial role in defining the future of smoke house validation. As authorities worldwide move towards stricter food safety standards, the need for robust validation processes has never been more pressing. Smoke house operators must stay informed about evolving regulations that may impact their practices. Compliance with these standards will likely require more comprehensive validation protocols and documentation practices.

In addition to these technological and regulatory trends, there is a growing emphasis on sustainability within the smoke house industry. Operators are increasingly seeking eco-friendly practices, including the use of sustainable wood sources and energy-efficient smoking equipment. This commitment to sustainability is not just a market differentiator; it reflects a broader industry shift towards environmental responsibility, which will undoubtedly influence future smoke house qualification and validation processes.

Why Thermal Process Validation is Crucial for Canned Food Manufacturers? Canned foods are a convenient and long-lasting option for consumers,...

Navigating FDA Regulations: FCE Registration and SID Filings It is widely known in the canning industry that the U.S. Food...

Thermal Process Validation – Hot Fill & Hold July 6, 2025 The Hot-Fill-Hold method is a crucial processing technique specifically...

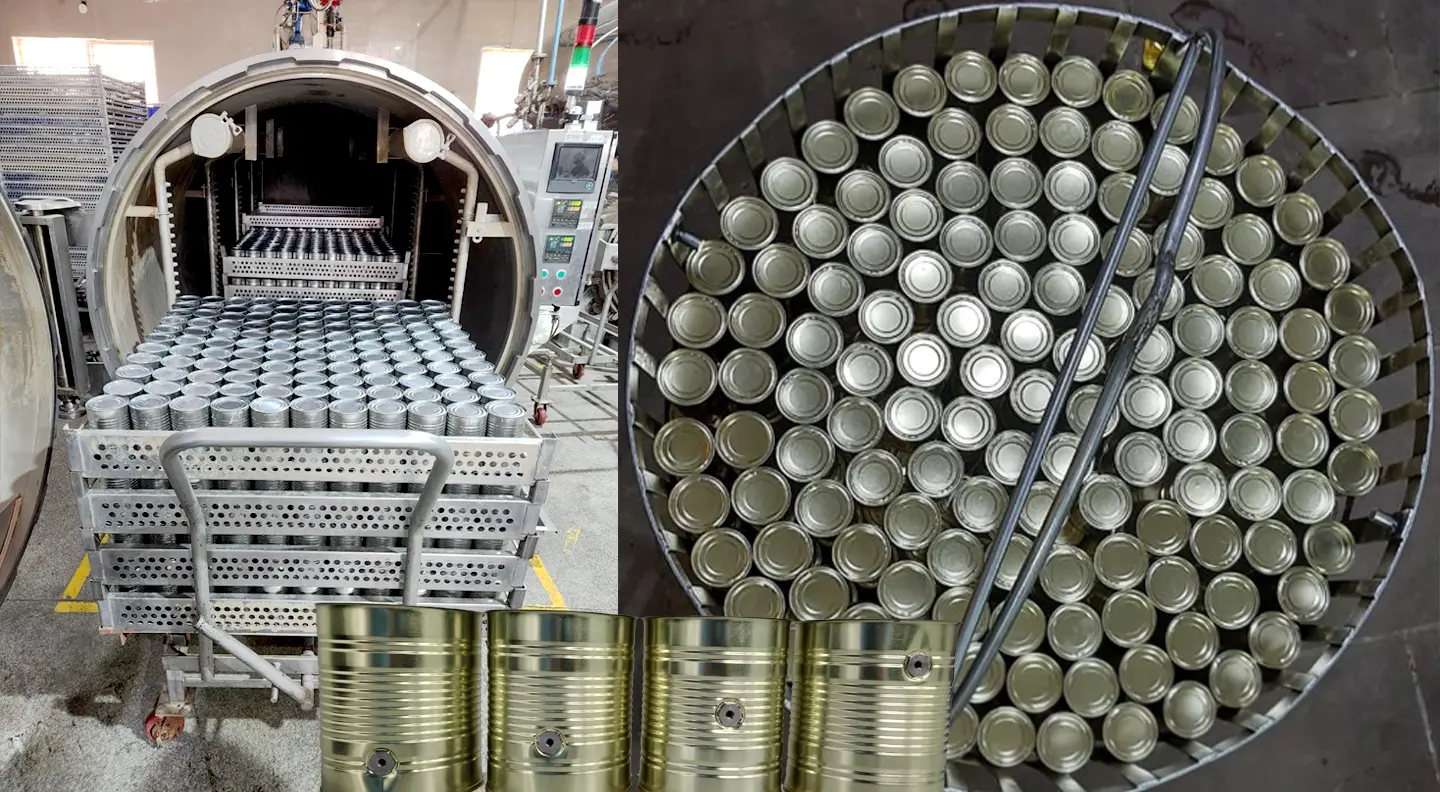

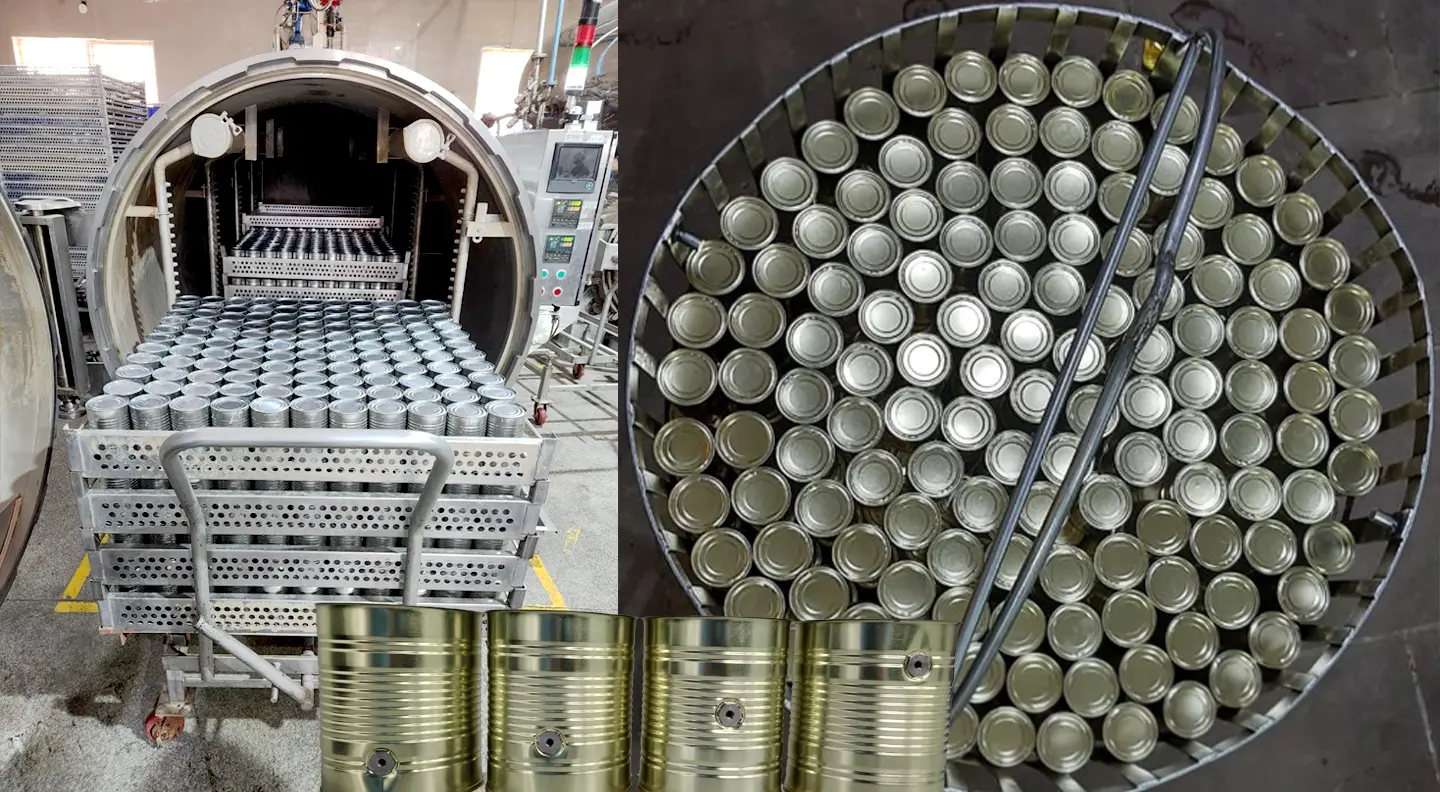

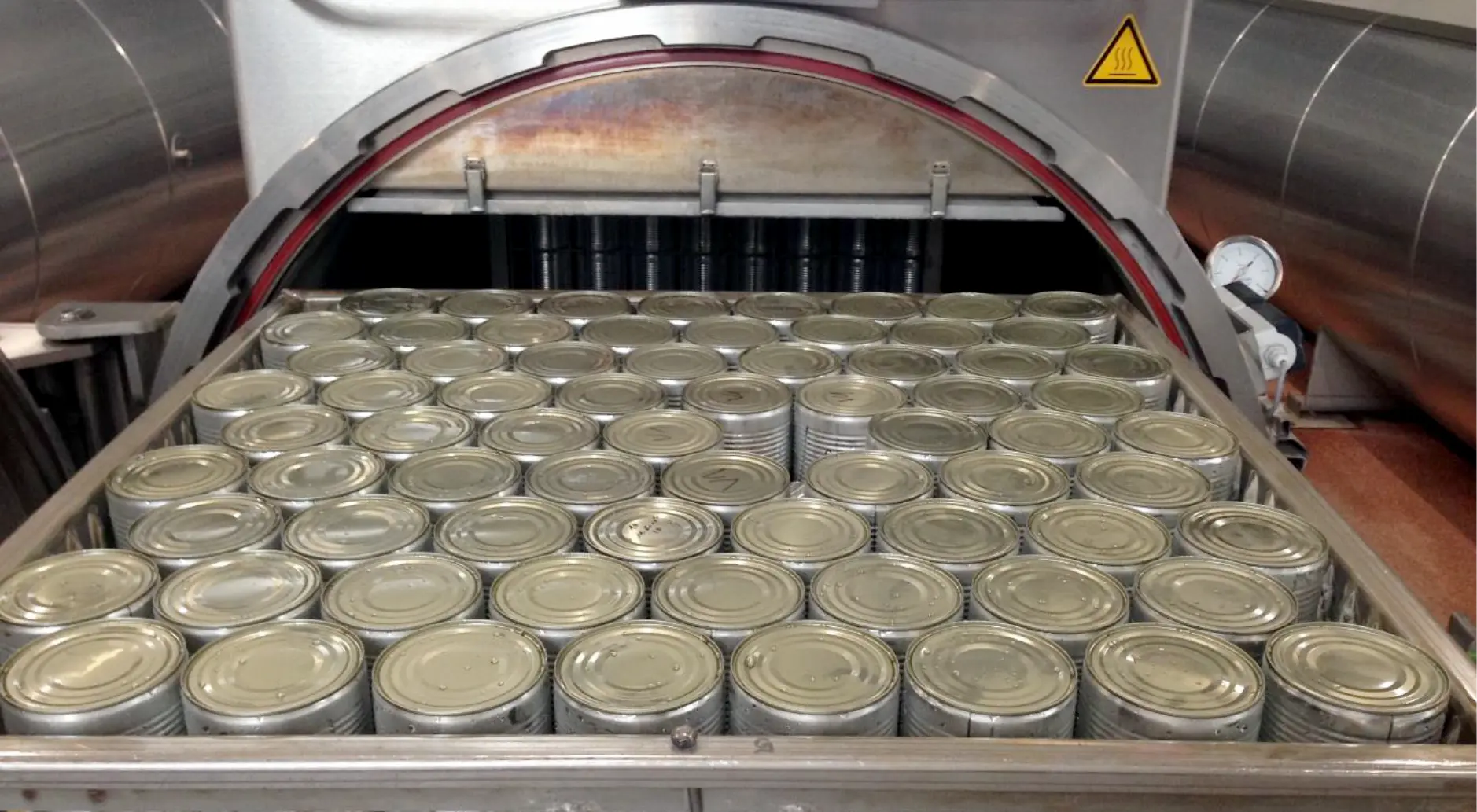

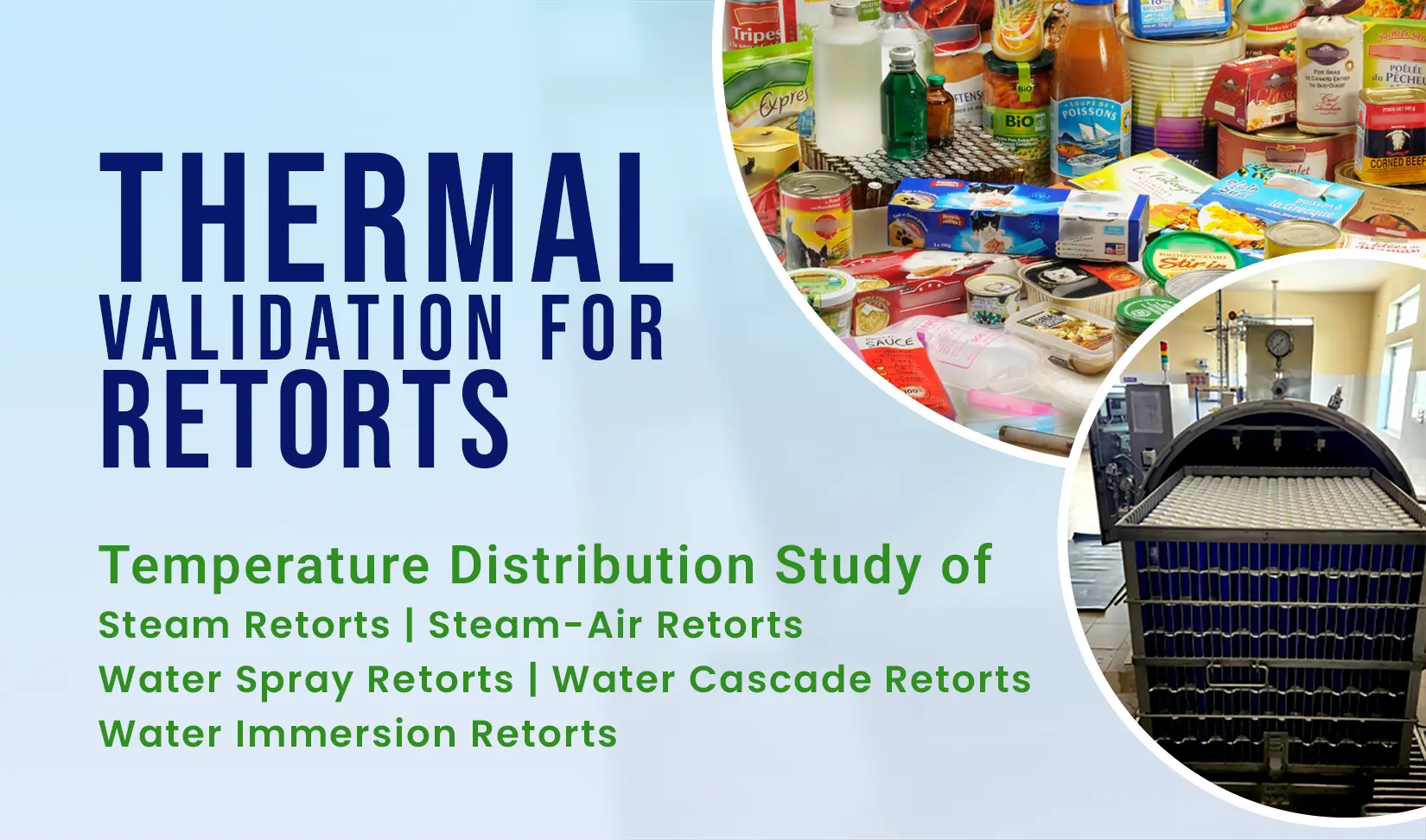

Retort Temperature Distribution Study and Product Heat Penetration Study Thermal processing, specifically a technique known as commercial sterilization, is a...

Thermal Process Authority in India Thermosoft Technologies has established itself as a leading thermal process authority in India, known for...

How to Ensure a Smooth Food and Beverage Sterilization Process? Ensuring a smooth food and beverage sterilization process is critical...

Ultimate Challenge in Retort Process: Finding the Balance between Food Safety & Quality For low-acid foods packed in the hermetically...

In-Container Sterilization – Ensuring Commercial Sterilization Through Critical Factors as per USFDA Guidelines Introduction:The term “Commercial Sterilization” refers to a...

Thermal validation is a crucial aspect of food processing that involves determining the effectiveness of heat treatment methods, particularly in...

At TST, we offer advanced process authority and validation services in support of thermally processed shelf-stable food products. Our teams are industry experts and come well-equipped with industry-leading thermal validation equipment